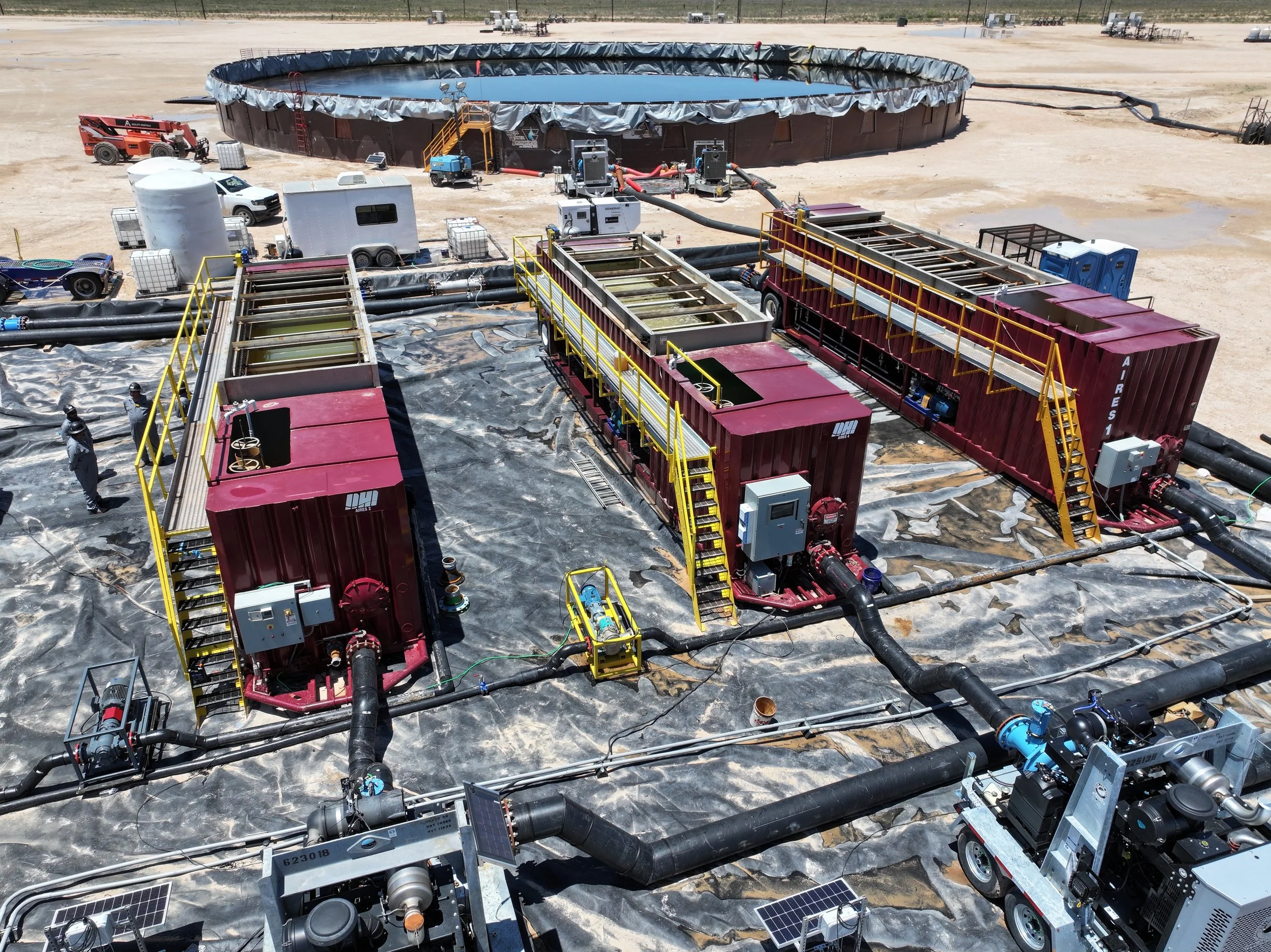

DISSOLVED AIR FLOTATION SYSTEM

DESCRIPTION

The DHI Dissolved Air Flotation system uses controlled micro-bubble generation to remove suspended solids and residual hydrocarbons from produced water with high efficiency and stable performance. The system is designed and manufactured by DHI and built into a standard frac tank footprint for rapid deployment and mobility in field environments.

All internal wetted surfaces are epoxy lined, and all insert components are constructed from 316 or 304 stainless steel to ensure corrosion resistance and prevent adverse chemical interaction with treated fluids. This design delivers long service life and consistent process reliability under harsh operating conditions.

The system incorporates DHI’s proprietary skimmer technology, optimized hydraulic process design, and precision level control systems to maintain steady separation performance across variable flow and loading conditions. Separated waste material is continuously evacuated from collection compartments, while clarified water flows to a buffer chamber for transfer to storage or downstream treatment.

The DAF integrates seamlessly with DHI oil separation, filtration, chemical dosing, and pumping systems, forming a complete treatment platform tailored to site-specific water quality and reuse requirements.

TECHNOLOGY

During operation, controlled micro-bubbles are generated and mixed with produced water containing suspended solids and residual hydrocarbons. The micro-bubbles attach to suspended particles, creating buoyant agglomerates that rise steadily to the surface. This forms a concentrated float layer, which is continuously removed by DHI’s proprietary skimming system. Clarified water remains below and is directed to downstream storage or additional treatment as required.

SPECIFICATIONS

• Dimensions: 46’L x 102”W x 122”H

• Weight: 23,458 lbs.

• Throughput: up to 100,000 BPD (subject to water quality input & output specification)

• Power needs: 60 KVA 480VAC

• DAF Aeration Pump 40 HP

• Skimmer Variable speed, continuous or intermittent

• Remote surveillance data telemetry (optional)

• Detachable walkway

• Adjustable weir

ADVANCED FEATURES & BENEFITS

• Built-in level protection and automated pump flow control

• Emergency stop systems for safe field operation

• High-performance whitewater pumps for consistent micro-bubble generation

• Optional oxygen-enriched whitewater for enhanced flotation efficiency

• Fast mobilization and commissioning

• Adjustable whitewater control for varied treatment objectives

• Hot-swap skimming assembly for minimal downtime

• Heavy-duty construction designed for long service life in harsh environments