Description applications

On-the-fly blending fresh and produced water

Automates blending using electronic sensors controlling blending valve to maintain TDS concentration at the desired level

Real-time TDS data logging and transmission

Benefits

Records water parameters throughout frac operations

Reduces the consumption of valuable freshwater

Environmentally beneficial using produced water for frac operations vs. freshwater

Meters and records flow rates during operation.

Cloud-connected data that can be made available to the customer in real-time

Easy to operate and adjust set points

It also serves as an ideal chemical injection point for additives.

Highly efficient blending reaching a homogenous blend within 5 ft of the comingle point

FEATURES

Data Acquisition of flow rates and TDS in real-time to cloud storage

Can be connected to remote pumps to jockey flow rates via cellular and satellite comms

Manual override capability

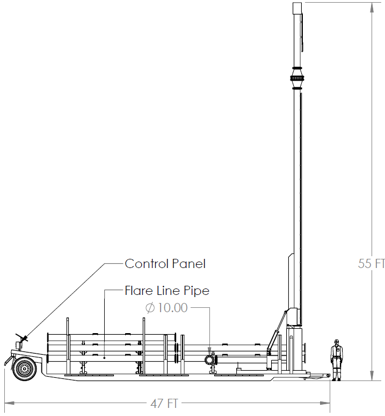

Skid Mount easy deployment